Product Description

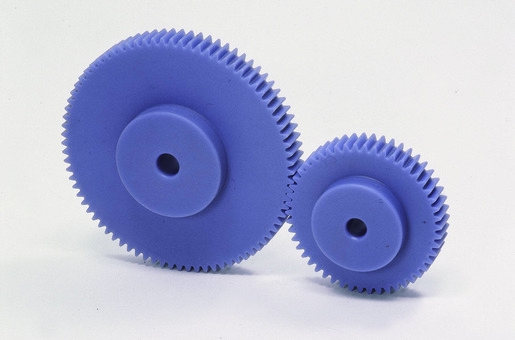

custom spur cnc plastic nylon pom flexible gear rack and pinion for linear motion

ZheJiang Enginnering Plastics Industries (Group) co., Ltd established in January 2009 , is a professional production

of “engineering plastics accessories” high-tech enterprises. Company main products : UHMW-PE , MC Nylon , PA6 ,

POM, HDPE , ABS , PU , PC , PVC, PP , PET , PBT , Acrylic, PEEK, PPS , PTFE , PVDF , PAI, PEI , PSU , PI, PBI

Antistatic product series . Company also provide wide range of accessories processing conditions , such as mass

customization production ability , exquisitemanufacturing technology and advanced production equipment , professional

technical advice and after-sales service. Companies strictly enforce the ISO9001(2008) International quality certification

system , the product quality conforms to the EU Rohs standard .

| Name | Plastic nylon6 sleeve |

| Material | High Performance Engineering Plastics–100% Virgin Nylon6 Raw Material. |

| Color | Nature color / Customized |

| Advantage | 1.Very good sliding properties even without lubrication 2.Good thermal mechanical bearing strength 3.Good chemical and hydrolysis resistance even against superheated steam 4.Very wear resistant 5.Very rigid 6.Light weight |

| Brand Name | Engineering Plastics / OEM |

| Size | Custom made as your drawing or sample |

| Density | 1.2g/cm3 |

| Manufacture way | Molding Injection and CNC Machinery process |

| MOQ | Accept the Sample order, and supply good price for the big quantity order. |

| Certification | ISO9001,SGS,FDA,RoHS,Test Report,ect. |

| Sample | Free the molding injection sample for customers after paying the mould Cost. |

| Sample time | 30 Days for manufacturing the injection mould and finished the samples for Customers. |

| Mass production time | 10-30 days based on the order quantity. |

| Payment | PayPal, Escrow, Western union, Money Gram, T/T and Alibaba Trade Assurance. |

| Packing | 5-ply environment-friendly corrugated boxes/ Plastic Pallets/ Wooden Pallets/ wooden cartons/ 20 feet Container / 40feet Container/ Customized |

| Other | 24 hours instant and comfortable customer service. Shipping status notification during delivery. Regular notification of new styles & hot selling styles |

1, thread H4 fine car grade tolerance 4H fine car grade production, vertical accuracy 0.005mm

2, high strength steel hardness HRC28, phosphoric acid plating on the surface and after lubrication

Each lock nut is provided with independent packaging to ensure qualitySpecializing in the production of “engineering plastic accessories” of high-tech enterprises, the company has a set of

imported production equipment and CNC processing equipment, processing means advanced, strong technical force.The company has rich experience, strong strength and participated in many high-end exhibitions;Many partners from

other countries are visitingQ1. We don’t have drawings, can we produce according to the samples we provide?

A1. OK

Q2. How to customize plastic parts?

A2. Customized according to drawings

Q3. Can I make a sample for testing first?

A3. OK

Q4. How long is the proofing cycle?

A4. 2-5 days

Q5. What are your processing equipment?

A5. CNC machining center, CNC lathe, milling machine, engraving machine,injection molding machine, extruder, moldin

machine

Q6. What craftsmanship do you have for processing accessories?

A6. According to different products, different processes are used, such as machining, extrusion, injection molding, etc.

Q7. Can injection products be surface treated? What are the surface treatments?

A7. OK. Surface treatment: spray paint, silk screen, electroplating, etc.

Q8. Can you help assembling the product after it is made?

A8. OK.

Q9. How much temperature can the plastic material withstand?

A9. Different plastic materials have different temperature resistance, the lowest temperature is -40ºC, and the highest

temperature is 300ºC. We can recommend materials according to the working conditions of your company.

Q10. What certifications or qualifications does your company have?

A10. Our company’s certificates are: ISO, Rohs, product patent certificates, etc.

Q11. How scale is your company?

A11. Our company covers an area of 2,000 square CHINAMFG and has 100 employees. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Color: | Natural, White, Black, Green, Blue, and So on |

|---|---|

| Density: | 1.6 |

| Transport Package: | Packing in Plastic Bags, Cartons, Wooden Ca |

| Specification: | Customized |

| Trademark: | Guangzhou Engineering Plastics |

| Origin: | Guangzhou, China |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can plastic gears withstand high torque and load conditions?

Plastic gears have certain limitations when it comes to withstanding high torque and load conditions. Here’s a detailed explanation of their capabilities:

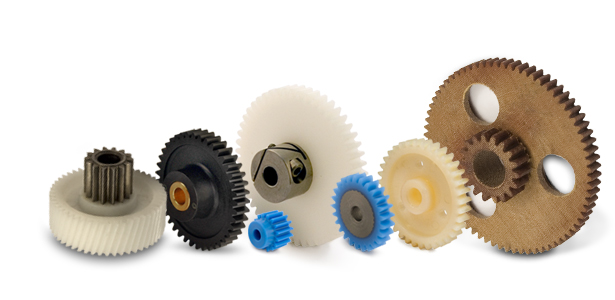

Plastic gears can be designed and manufactured to handle a range of torque and load conditions, but their performance is generally inferior to that of metal gears in high-stress applications. The specific capabilities of plastic gears depend on various factors, including the chosen plastic material, gear design, tooth profile, and operating conditions.

While plastic gears may not be suitable for extremely high torque or heavy-load applications, they can still provide reliable performance in many moderate-load scenarios. Plastic gears are commonly used in applications with light to moderate loads, where their unique properties and advantages outweigh their limitations.

Some plastic materials, such as acetal (POM) and polyamide (nylon), offer good strength and wear resistance, allowing them to handle moderate torque and load conditions. These materials can be reinforced with additives or fillers to enhance their mechanical properties and increase their load-bearing capacity.

It’s important to note that when designing with plastic gears, engineers must carefully consider factors such as gear size, tooth geometry, material selection, and operating conditions. Reinforcement techniques, such as using metal inserts or reinforcing fibers, may be employed to improve the strength and load-bearing capabilities of plastic gears in certain applications.

In high torque or heavy-load applications, metal gears, particularly those made from steel or other high-strength alloys, are generally preferred due to their superior strength and durability. Metal gears offer higher load capacities, better resistance to deformation, and increased resistance to wear under extreme conditions.

Ultimately, the suitability of plastic gears for high torque and load conditions depends on the specific requirements of the application and the trade-off between the benefits of plastic gears, such as weight reduction and noise reduction, and the higher load-bearing capabilities of metal gears.

It’s recommended to consult with gear manufacturers or mechanical engineers to determine the most appropriate gear material and design for a particular application, especially when high torque and load conditions are expected.

Can plastic gears be used in automotive applications?

Yes, plastic gears can be used in automotive applications. Here’s a detailed explanation:

Plastic gears have several advantages that make them suitable for certain automotive applications. They are lightweight, have good wear resistance, offer design flexibility, and can operate with low noise levels. However, it’s important to consider the specific requirements and limitations of automotive applications before using plastic gears.

1. Non-load Bearing Applications: Plastic gears are commonly used in non-load bearing applications within automotive systems. These include applications such as instrument clusters, HVAC systems, seat adjustments, and interior components. In these cases, the gears are subjected to relatively low loads and can effectively perform their functions while offering benefits such as weight reduction and cost efficiency.

2. Auxiliary Systems: Plastic gears can also be used in auxiliary systems of vehicles, such as windshield wipers, window regulators, and sunroof mechanisms. These systems typically operate at lower loads and speeds compared to primary powertrain components. Plastic gears can provide reliable performance in these applications while contributing to weight reduction and improved fuel efficiency.

3. Noise and Vibration: Plastic gears have inherent damping properties that can help reduce noise and vibration in automotive applications. This is particularly advantageous in areas where noise reduction is a priority, such as electric window mechanisms or HVAC systems. Plastic gears can contribute to a quieter and more comfortable driving experience.

4. Design Flexibility: Plastic gears offer design flexibility, allowing for complex shapes and customization to meet specific automotive requirements. They can be molded with precision to achieve intricate gear profiles and optimize gear performance. The flexibility in design can lead to improved efficiency, reduced weight, and space-saving advantages in automotive systems.

5. Material Selection: The selection of the appropriate plastic material is crucial for automotive applications. Certain plastic materials, such as engineering thermoplastics like POM (polyoxymethylene) or PA (polyamide), offer higher strength, rigidity, and wear resistance compared to standard plastics. These materials can withstand the demands of automotive environments, including temperature variations and exposure to chemicals or oils.

6. Load-Bearing Applications: While plastic gears are commonly used in non-load bearing or low-load applications within the automotive industry, they may have limitations in high-load or high-torque applications. Metal gears, such as steel or cast iron, are generally preferred for primary powertrain components such as transmissions and differential systems, where higher strength and durability are required to handle the significant loads and forces involved.

7. Environmental Considerations: Automotive applications can expose gears to various environmental factors such as temperature extremes, humidity, UV radiation, and exposure to chemicals or oils. The selected plastic material should have good resistance to these environmental conditions to ensure long-term durability and performance.

In summary, plastic gears can be successfully used in certain automotive applications, particularly in non-load bearing or low-load scenarios, as well as in auxiliary systems. They offer advantages such as weight reduction, design flexibility, and noise reduction. However, when considering the use of plastic gears in automotive applications, it’s important to carefully evaluate the specific requirements, loads, environmental conditions, and material selection to ensure optimal performance and durability.

Can plastic gears replace metal gears in certain applications?

Yes, plastic gears can replace metal gears in certain applications. Here’s a detailed explanation:

Plastic gears offer a range of advantages that make them suitable alternatives to metal gears in specific scenarios. Some of the factors that determine whether plastic gears can replace metal gears include the application requirements, operating conditions, load capacity, and desired performance characteristics.

Advantages of Plastic Gears:

- Lightweight: Plastic gears are significantly lighter than metal gears, making them suitable for applications where weight reduction is important. This can lead to energy efficiency, reduced inertia, and lower wear on supporting components.

- Low Noise and Vibration: Plastic gears have inherent damping properties that help reduce noise and vibration levels during operation. This makes them suitable for applications where noise reduction is desired, such as in consumer electronics or office equipment.

- Corrosion Resistance: Certain plastic materials used in gear manufacturing exhibit excellent resistance to corrosion and chemicals. Plastic gears can be a suitable choice for applications in corrosive environments where metal gears may suffer from degradation.

- Self-Lubrication: Some plastic materials used for gear manufacturing have self-lubricating properties. This reduces friction and wear between gear teeth, eliminating the need for external lubrication and simplifying maintenance requirements.

- Cost-Effective: Plastic gears can be more cost-effective compared to metal gears, especially in large-scale production. Plastic materials are often less expensive than metals, and the manufacturing processes for plastic gears can be more efficient.

- Design Flexibility: Plastic gears offer greater design flexibility compared to metal gears. They can be molded into complex shapes, allowing for custom gear profiles and tooth geometries, resulting in optimized performance and efficiency for specific applications.

Limitations of Plastic Gears:

- High Torque and Load Capacity: Plastic gears may not have the same torque and load capacity as metal gears. In applications requiring high torque or heavy loads, metal gears may be more suitable due to their higher strength and durability.

- High Temperatures: Plastic gears have temperature limitations depending on the chosen material. In applications with high operating temperatures, metal gears that can withstand the heat may be necessary.

- Precision and Positioning: Plastic gears may not offer the same level of precision and positioning accuracy as metal gears. Applications that require tight tolerances and precise gear meshing may still require metal gears.

In summary, plastic gears can replace metal gears in certain applications where their advantages align with the specific requirements and operating conditions. It’s crucial to carefully evaluate the application needs, load capacity, temperature range, and other factors to determine if plastic gears are suitable replacements for metal gears.

editor by CX 2024-04-17