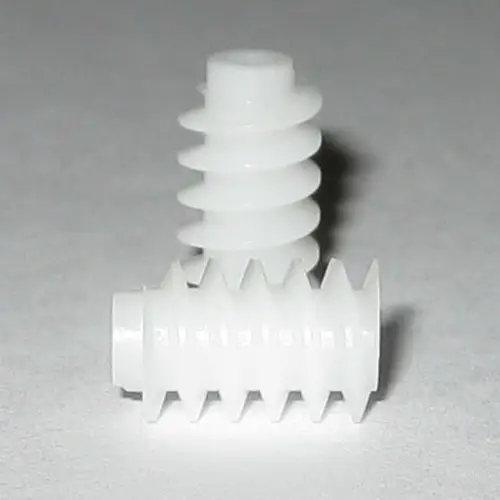

Plastic Worm Gear Live Demonstration

Introduction

In this article, we will explore the fascinating world of plastic worm gear live demonstration and its relationship with Plastic worm gear. Plastic worm gear live demonstration is an immersive experience that showcases the functionality and benefits of Plastic worm gear in various applications. This live demonstration allows viewers to witness the intricate workings of Plastic worm gear firsthand, highlighting its durability, efficiency, and versatility.

Informational Connection

Plastic worm gear live demonstration serves as an excellent platform to bridge the gap between theoretical knowledge and practical application. By observing the live demonstration, one can gain a deeper understanding of how Plastic worm gear operates and its potential applications. This interactive experience allows viewers to grasp the concept of Plastic worm gear more effectively, enabling them to make informed decisions when implementing this technology.

Performance Characteristics

- High torque transmission

- Low noise and vibration

- Self-locking feature

- Excellent wear resistance

- Wide temperature range

Plastic worm gear offers exceptional torque transmission capabilities, making it suitable for heavy-duty applications.

Thanks to its precise design and advanced materials, Plastic worm gear operates with minimal noise and vibration, ensuring a smooth and quiet performance.

Plastic worm gear exhibits a self-locking attribute, which prevents backward motion and enhances stability in various systems.

With the use of high-quality materials and advanced manufacturing techniques, Plastic worm gear demonstrates remarkable wear resistance, ensuring a prolonged lifespan.

Plastic worm gear can withstand extreme temperature conditions, making it suitable for both high and low-temperature environments.

Types and Advantages

Plastic worm gear is available in various types, each with its own unique characteristics. Some common types include:

1. Nylon Plastic Worm Gear

Nylon Plastic worm gear offers excellent strength and durability, making it ideal for heavy-duty applications. It is also resistant to chemicals and corrosion, ensuring reliable performance in challenging environments.

2. Acetal Plastic Worm Gear

Acetal Plastic worm gear provides superior dimensional stability and low friction properties. Its self-lubricating nature eliminates the need for additional lubrication, reducing maintenance requirements.

3. Polyethylene Plastic Worm Gear

Polyethylene Plastic worm gear is known for its exceptional impact resistance and low moisture absorption. It is widely used in applications where high shock loads and moisture exposure are present.

4. Polypropylene Plastic Worm Gear

Polypropylene Plastic worm gear offers excellent chemical resistance and electrical insulation properties. It is commonly utilized in chemical processing and electrical equipment applications.

5. PEEK Plastic Worm Gear

PEEK Plastic worm gear exhibits outstanding mechanical and thermal properties, making it suitable for high-temperature and high-stress applications. Its superior resistance to wear and chemicals further enhances its reliability.

Each type of Plastic worm gear possesses specific advantages, catering to diverse industry requirements. The selection of the appropriate Plastic worm gear depends on the specific application demands, ensuring optimal performance and longevity.

Applications in Various Fields

Plastic worm gear finds extensive usage in multiple industries, including:

1. Construction Equipment

In the construction industry, Plastic worm gear is utilized in crane systems, concrete mixers, and lifting mechanisms. Its robust design and high torque capabilities make it ideal for heavy construction applications.

2. Industrial Machinery

Plastic worm gear plays a crucial role in industrial machinery such as conveyors, packaging equipment, and material handling systems. Its efficient power transmission and low noise properties contribute to the smooth operation of these machines.

3. Automotive Industry

In the automotive sector, Plastic worm gear is employed in steering systems, windshield wiper mechanisms, and power windows. Its self-locking feature and durability ensure optimum performance and safety in these automotive applications.

4. Textile Industry

Within the textile industry, Plastic worm gear is utilized in weaving machines, spinning frames, and yarn guiding systems. Its precise motion control and longevity enable high-quality fabric production.

5. Marine Applications

Plastic worm gear finds extensive usage in marine applications such as boat winches, anchor mechanisms, and steering systems. Its corrosion resistance and ability to withstand harsh marine environments make it an ideal choice.

Future Trends and Opportunities

The future of Plastic worm gear products is promising, with several trends and opportunities emerging in the industry:

1. Increasing Demand for Lightweight Solutions

As industries strive for more energy-efficient and environmentally friendly solutions, the demand for lightweight Plastic worm gear is expected to rise. Lightweight materials offer improved efficiency and reduced energy consumption.

2. Advancements in Material Technology

Ongoing research and development in material science are leading to the development of advanced materials that offer enhanced performance and durability. These advancements will further expand the capabilities of Plastic worm gear in various applications.

3. Growing Automation in Industries

The increasing adoption of automation in industries creates new opportunities for Plastic worm gear. Its precise motion control and reliable performance make it an essential component in automated systems.

4. Expansion in Renewable Energy Sector

With the global focus on renewable energy sources, the demand for Plastic worm gear in wind turbines, solar panels, and hydroelectric systems is expected to grow. Plastic worm gear’s ability to handle high torque and harsh environmental conditions makes it a suitable choice for renewable energy applications.

5. Emphasis on Cost-Effective Solutions

Cost-effectiveness remains a prominent factor in the selection of components. Plastic worm gear’s competitive pricing, coupled with its excellent performance and longevity, positions it as a cost-effective solution in various industries.

Choosing the Right Plastic Worm Gear

When selecting the appropriate Plastic worm gear, several factors should be considered:

1. Clearly Define the Requirements

Understanding the specific application requirements, including torque, speed, and environmental conditions, is crucial in choosing the right Plastic worm gear.

2. Material Selection

Selecting the appropriate material based on factors such as strength, chemical resistance, and temperature tolerance ensures optimal performance and longevity.

3. Design Optimization

Collaborating with experienced engineers to optimize the design of the Plastic worm gear system maximizes its efficiency and functionality.

4. Supplier and After-Sales Service

Choosing a reliable supplier that provides excellent after-sales service ensures ongoing support and assistance throughout the product’s lifespan.

5. Cost-Effectiveness

Balancing the cost of the Plastic worm gear with its performance and longevity helps achieve a cost-effective solution without compromising quality.

Maintenance of Plastic Worm Gear

To ensure the longevity and optimal performance of Plastic worm gear, the following maintenance practices should be followed:

1. Regular Equipment Inspection

Performing routine inspections to detect any signs of wear, misalignment, or damage allows for timely maintenance and replacement of components.

2. Cleaning and Corrosion Prevention

Regularly cleaning the Plastic worm gear system and implementing appropriate corrosion prevention measures help maintain its performance and prevent degradation.

3. Lubrication and Maintenance

Applying suitable lubricants and performing regular maintenance tasks, such as adjusting backlash and checking gear mesh, ensures optimal functioning of Plastic worm gear.

4. Replacement of Worn Parts

Identifying and replacing worn or damaged components in a timely manner is essential to avoid further damage and system inefficiencies.

5. Continuous Improvement and Upgrades

Monitoring the performance of the Plastic worm gear system and implementing improvements or upgrades as necessary helps enhance its efficiency and adaptability.

Why Choose Us

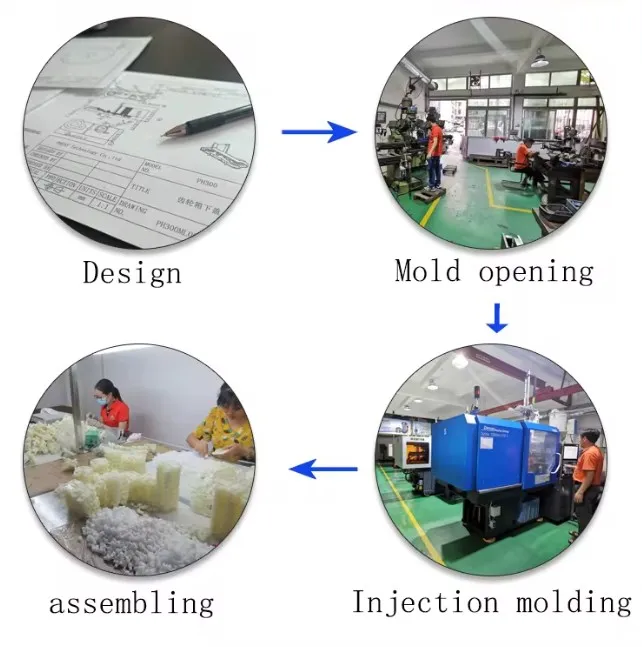

At our company, we specialize in the manufacturing and sale of Plastic worm gear. We pride ourselves on the following advantages:

1. Extensive Industry Experience

With years of experience in the industry, we have gained valuable expertise and insight into the production and application of Plastic worm gear.

2. High-Quality Products

Our Plastic worm gear products undergo rigorous quality control measures to ensure they meet the highest standards of performance and durability.

3. Customization Options

We offer customization options to tailor Plastic worm gear solutions to specific customer requirements, ensuring optimal functionality and performance.

4. Timely Delivery

We understand the importance of prompt delivery. Our efficient logistics and production processes ensure timely delivery of Plastic worm gear products to our customers.

5. Excellent Customer Support

We prioritize customer satisfaction and provide comprehensive after-sales support, including technical assistance and guidance, to address any queries or concerns.

Q&A

1. Can Plastic worm gear be used in high-temperature environments?

Yes, certain types of Plastic worm gear, such as PEEK Plastic worm gear, exhibit excellent thermal resistance and can operate effectively in high-temperature environments.

2. Which industries benefit the most from Plastic worm gear?

Plastic worm gear finds applications in a wide range of industries, including construction, automotive, textile, marine, and industrial machinery.

3. Is lubrication required for Plastic worm gear?

While some Plastic worm gear types possess self-lubricating properties, others may require additional lubrication. It is essential to refer to the manufacturer’s guidelines for specific maintenance requirements.

4. Can Plastic worm gear withstand harsh chemical environments?

Yes, certain types of Plastic worm gear, such as Nylon and Polypropylene, exhibit excellent chemical resistance, making them suitable for use in harsh chemical environments.

5. Are there size limitations for Plastic worm gear?

Plastic worm gear is available in various sizes, catering to different application requirements. Customization options are also available for specific size needs.

Author: Dream